Abrasif cryogénique

Cryogenic abrasive

Regardless of the cryogenic deburring application, achieving satisfactory results with maximum efficiency requires high levels of consistency across all aspects of the shot peening process.

DIEBLAST SYSTEMS maintains strict control of the cryogenic blast media, which is essential to obtain any hope of overall consistency between abrasive and turbine blasting.

Some cryogenic abrasive producers use second grade regrind polymer or reprocessed material in their product, which leads to poor results and ultimately failures in the deburring process.

DIEBLAST SYSTEMS uses only superior quality virgin polymers in their cryogenic abrasives thus ensuring continuity of the quality generated.

The unique cutting system developed by DIEBLAST SYSTEMS produces a cleaner, more precise pellet profile and a high quality, therefore more consistent, cryogenic deburring performance.

The -40°C shot peening criteria for EPDM O-rings, are completely different from those required for "flash freezing" and deburring a silicone overmold at -120°C.

Experience has shown that the quality of cryogenic abrasive with a cryogenic blasting system is the most important factor in controlling cost and quality of the entire application process.

For more than 29 years, DIEBLAST SYSTEMS has developed cryogenic products to meet the demand of end users and blasting equipment manufacturers.

Advantages of our Cryogenic abrasives :

- Dimensional stability over a wide temperature range

- Low abrasion for maximum durability

- High molecular weight polymers

- High impact resistance very low temperature

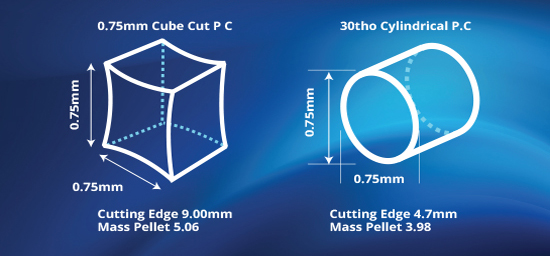

- Cube or Cylindrical formats

- No lot-to-lot variation

Shapes of our cryogenic abrasive

A non-standard grain size is also possible. Use our contact form to request a technical sheet.

CUBIC GRANULOMETRY

| Product | Size in mm | Diagonal in mm | Mass |

|---|---|---|---|

| 0.503 | 0.50 | 0.88 | 0.15 |

| 0.753 | 0.75 | 1.32 | 0.50 |

| 1.003 | 1.05 | 1.67 | 1.40 |

| 1.253 | 1.25 | 2.10 | 2.34 |

| 1.503 | 1.50 | 2.64 | 4.05 |

| 2.003 | 2.00 | 3.50 | 9.60 |

CYLINDRICAL GRANULOMETRY

| Product | Size in mm | Diagonal in mm | Mass |

|---|---|---|---|

| 20tho | 0.50 x 0.50 | 0.75 | 0.12 |

| 30tho | 0.76 x 0.76 | 1.07 | 0.41 |

| 45tho | 1.14 x 1.14 | 1.61 | 1.40 |

| 60tho | 1.50 x 1.50 | 2.15 | 3.18 |

| 80tho | 2.00 x 2.00 | 2.87 | 7.54 |

| 125tho | 3.00 x 3.00 | 4.38 | 25.45 |